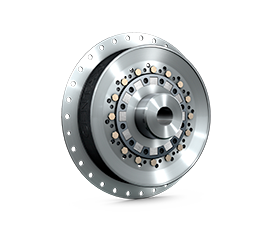

Uncompromising, Easy to Install and Highly Flexible

CENTAX torsional couplings are built for diesel and gas driven compressors, pump drives, and similar industry applications. Economical, easy to mount, and simple to install, the CENTAX couplings are a no-fuss solution built with unparalleled quality. The torsionally soft CENTAX couplings feature a rubber-in-shear element with high torsional and radial flexibility. The coupling designs can be plugged in axially for maximum ease of mounting. The cost-effective, compact design makes the CENTAX portfolio a superior solution for many applications. With many options and variations to increase damping qualities, compensate for axial, angular, and radial misalignments, and cover a range of torques from 400 to 800,000 Nm, there are a vast array of solutions within the CENTAX portfolio.

CENTAX Coupling

CENTA FH

The CENTA-FH is a flange housing with internal taper bearing support to protect engine crankshafts from the reaction forces coming from high angle cardan shaft connections. The CENTA-FH compensates high forces resulting from large deflection angles of the connected components. The CENTA-FH transmits reaction forces to the engine housing for the protection of the crankshaft bearings. This robust flanged bearing housing is made of tempered aluminum. With a lightweight, compact design, the CENTA-FH bearing housing is extremely easy to maintain and durable. Features extensive ventilation to reduce the ambient temperature. Available with a speed-controlled centrifugal clutch for soft engagement of connected components, the CENTA-FH provides ideal torsional vibration tuning and minimum mounting and maintenance. The bearing housing is shipped pre-assembled as a unit for SAE standard flywheel connections.

CENTAX-V

CENTAX-V series includes torsionally soft intermediate couplings and bearing support for universal joint shafts designed for construction equipment, ship propulsion drives, and locomotives. This versatile, highly torsionally flexible intermediate coupling has linear characteristics. For cardan driveshafts, the CENTAX-V series provides the safe transmission of torque via a highly flexible, pre-compressed rubber-in-shear element with precision-centered bearings built in. A highly flexible intermediate coupling like the CENTAX-V assures damping of the vibrations and noise for smooth operation and a longer service life for connected units and gear. The CENTAX-V is ventilated with a high allowable energy loss to ensure good heat dissipation and prevent overheating during operation. The couplings are economically priced, and readily available with several standard SAE flywheel connections and hubs to suit a variety of shaft flanges. CENTA-FH flange housings are recommended for larger deflection angles.

CENTAX-TT

Ideal for heavy-duty and high-speed applications, the CENTAX-TT is a compact twin torque coupling with high performance. Designed with two concentrically arranged, pre-compressed “twin” rubber segments to jointly transmit torque, the CENTAX-TT is a high-performing design specifically built for a high torque range. Used for ship propulsion, generator sets, and similar applications, the CENTAX-TT is characterized by medium torsional stiffness. Torsional adaptation can be achieved by adjusting the number and arrangement of the rubber segments to allow for many different configurations. The CENTAX-TT damps torsional vibrations and shock loads. Able to compensate axial and radial misalignments, this flexible coupling is an ideal solution. Effectively ventilated for high admissible energy loss, the CENTAX-TT can hold up under many tough environments. Mounted with minimal effort and replaceable without movement of surrounding coupled components, the CENTAX-TT is a compact, low-maintenance coupling solution.

CENTAX-KS

Part of the CENTAX-K line, the CENTAX-KS features a hub integrated into the plastic flange on the driven-side. The driving unit of this one-piece coupling is then plugged onto the splined shaft of your driven equipment for ease of assembly. The CENTAX-KS is available in variations to suit many different applications. Able to damp torsional vibrations and impacts to reduce wear and tear on your gear or pump, the CENTAX-KS compensates for axial and radial misalignment that may result during operation. The series covers torques ranging from 400 to 800 Nm. Tested and proven, CENTA products can withstand the toughest applications.

CENTAX-KK

Under the CENTAX-K product line, the CENTAX-KK features a two-piece connection to the driven units. Using an additional hubstar from the CENTAFLEX-K series, an axial blind mount is achieved. The design allows for keyed connections, conical clamping, or the CENTALOC-clamping. The positive locking of the hub with an integrated rubber bumper provides additional innovation and customization, ensuring that the fixed rotating direction coupling is free of backlash. The innovative design ensures reduced noise during operation. Excellent for marine and energy applications, the CENTAX-KK has the quality features of the CENTAX-K, available customization, and superior adaptability for each application.

CENTAX-K

Built for diesel-driven compressor and pump drives, the CENTAX-K is a torsionally soft coupling based on a rubber-in-shear element vulcanized to a glass-fiber reinforced plastic flange. CENTAX-K’s reliable compensation of misalignments has been endurance-tested (type-tested), and proven. The CENTAX-K features a compact design and is available with a silicone elastomer for high-temperature applications. Plug-in features are available for simple equipment mounting. All standard flywheel connections are realized with the CENTAX-K for efficient, fast, and easily-customized solutions.