High Performance Design with High Flexibility

CENTAFLEX-A series couplings are designed for high-performance and high-torsional elasticity. Built to damp torsional vibrations and shocks, CENTAFLEX-A protects your equipment and outperforms others in its class. Able to compensate for significant axial, radial, and angular misalignment, CENTAFLEX-A addresses the most common coupling and bearing failure-related issues. The electrically-insulating and thermally-resistant silicone or rubber design is fail-safe and offers backlash-free torque transmission, even under high-torque applications.

CENTAFLEX-A series is available in a variety of designs, including an axially blind-fit design with radial mounting capacity. Couplings are available with a split rubber element for quick replacement and easy maintenance. Easily handled and readily mountable with minimum effort, the CENTAFLEX-A series torsional couplings are available in a variety of sizes and lengths for any installation requirement as a constant velocity shaft. Available in carbon-fiber and glass-fiber designs for endless configuration and customization.

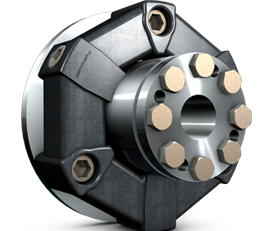

CENTAFLEX-A Coupling

CENTAFLEX-A Type 0-S

Flexible elements for CENTAFLEX-A Type 0-S couplings.

CENTAFLEX-A Type 0

Flexible elements for CENTAFLEX-A Type 0 couplings.

CENTAFLEX-AM

CENTAFLEX-AM is a highly flexible coupling, built for connecting marine gear output flanges with a propeller shaft, while isolating the boat hull from noise and vibration. The CENTAFLEX-AM provides backlash-free transmission of torque and propeller thrust using a highly flexible rubber element and thrust bearing. This coupling is specifically designed to reduce noise and vibrations, prolonging the life of surrounding equipment. The flexible coupling damps torsional vibrations and shock loads while offering a high degree of electrical insulation. Designed to compensate moderate axial, radial, and angular misalignments – a common cause of wear – the CENTAFLEX-AM is available in a wide range of standard sizes covering engine power up to several hundred kW. Easily mounted with a clamping hub, the CENTAFLEX-AM is delivered ready to install.

CENTAFLEX-ACV

CENTAFLEX-ACV is a highly flexible constant velocity driveshaft, ideal for the connection of marine gear output flanges to propeller shafts, and for applications with considerable angular deflections. The CENTAFLEX-ACV offers torque transmission via a double cardan driveshaft featuring a CV joint on one side and a highly flexible rubber element on the other. Ideal for marine use, a self-aligning thrust bearing transmits propeller thrust to the boat hull. Specifically designed to reduce noise, vibration, and shock, the CENTAFLEX-ACV damps torsional vibrations while offering electrical insulation as well. The CENTAFLEX-ACV tolerates angular deflections of up to 3 degrees. This driveshaft is easy to install and can be mounted with minimal effort thanks to the easy-to-use clamping hub.

CENTAFLEX-AGM

CENTAFLEX-AGM is a highly flexible constant velocity driveshaft ideal for connecting marine gear output flanges to propeller shafts in applications with moderate angular deflections. The CENTAFLEX-AGM offers backlash-free torque transmission with a double cardanic driveshaft, featuring two-highly flexible rubber elements. Ideal for marine use, propeller thrust is transmitted to the boat hull by a self-aligning thrust bearing. The CENTAFLEX-AGM is designed to reduce noise and minimize vibrations, ensuring less wear and tear on surrounding equipment. Built to damp torsional vibrations and shock loads, the CENTAFLEX-AGM tolerates angular deflections of up to 3 degrees. Additionally, the CENTAFLEX-AGM driveshaft offers a significant degree of electrical insulation. The driveshaft can be mounted with minimal effort using the clamping hub. Installation and maintenance are simple, and the product is delivered ready to install.

CENTAFLEX-M

CENTAFLEX-M is a highly flexible CENTAFLEX coupling designed to connect gear output flanges to a propeller shaft, specifically in applications where mounting space is limited. Featuring a highly flexible rubber element, the CENTAFLEX-M offers backlash-free transmission of torque and propeller thrust. Designed to reduce noise and vibration under small and confined spaces, the CENTAFLEX-M damps torsional vibrations and shocks while limiting structural noise and providing significant electrical insulation. Built compact, the CENTAFLEX-M reduces handling and maintenance costs by omitting the additional components typically needed, like spacers. The CENTAFLEX-M compensates axial, radial, and angular misalignments for added safety and reduced wear and tear. Easy to mount by using the clamping hub, the CENTAFLEX-M is an ideal solution for limited mounting spaces.

CENTAFLEX-A Drive Shafts

CENTAFLEX-A constant velocity driveshafts are available in various lengths to adapt to your needs and installation requirements. The highly flexible CENTAFLEX-A driveshafts are particularly well suited for use in marine, industrial, energy, and rail applications. The CENTAFLEX-A is a high-performer with high torsional elasticity. Built to damp torsional vibrations and shock loads, the CENTAFLEX-A element can compensate considerable axial, radial, and angular misalignments. Available in thin wall steel tube, carbon-fiber or glass-fiber designs, and with a split element option, the CENTAFLEX-A is easy to install and maintain with minimum effort. The electrically-insulating and thermally-resistant silicone element option offers a reliable, fail-safe, backlash-free transmission of high torques where needed.