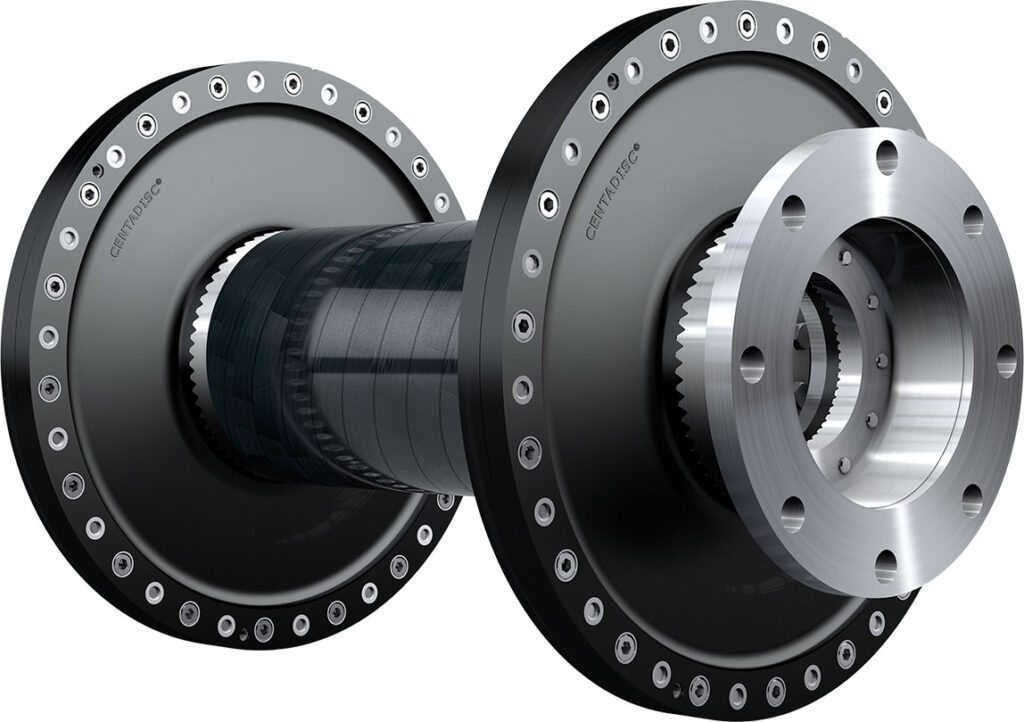

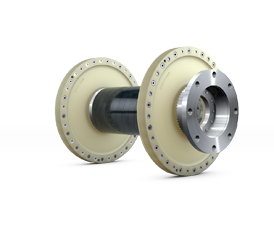

Reinforced Composite Design for Applications Where Low Weight and Flexibility are Critical

CENTADISC-C Coupling

CENTADISC-C

The CENTADISC-C series torsionally stiff couplings and driveshafts offer a cost-effective, low-maintenance solution for vibration and noise-damping. The lightweight composite materials ensure safe transmission of high torques and speeds. Built with modularity, CENTADISC-C can be combined with additional CENTA torsional coupling products for optimal adaptation and performance. Standardized shaft-end face-tooth connections between the coupling membrane elements and tube or power unit ensures easy installation and low maintenance. The CENTADISC-C is ideal for applications with demanding misalignments, high speed, long spans, and corrosive environments. Rely on CENTADISC-C products for smooth, no-hassle performance, strength, and optimum durability in marine, rail, and similar applications.